| Min. Order: | 1 Others |

|---|

Basic Info

Model No.: .Z28-200.

Additional Info

Brand: BoRong

Transportation: Ocean

Place of Origin: HeBei of China

Product Description

Product Usage

The thread rolling machine uses the cutting and rolling thread to form the steel bar end reinforcement and thread processing, solves the problem of pre-treatment of the steel bar before processing, and the problem that the same kind of equipment needs to be rolled many times. In this way, the process reduces the number of process processing and multiple steel bar handling, and improves the on-site production and processing efficiency; the thread rolling machine can realize the rolling processing of various specifications of steel bars by using one rolling wire head, and solves the straight processing of the steel bar end by the same kind of equipment. Threads require a single bobbin head for each size. The thread rolling machine adopts the internal coolant to solve the problem of chip removal during the rolling process, and the automation intensity is high, and the automatic stop and reset of the feed automatically stops. The steel stripping rib straight thread rolling machine is a special equipment for processing straight steel thread heads. The ends of the steel bars are stripped by a stripping rib cutter, and then the steel bars are rolled straight by three hollow rolling wheels to achieve straight steel bars.forming that quality requirements for thread

Product description

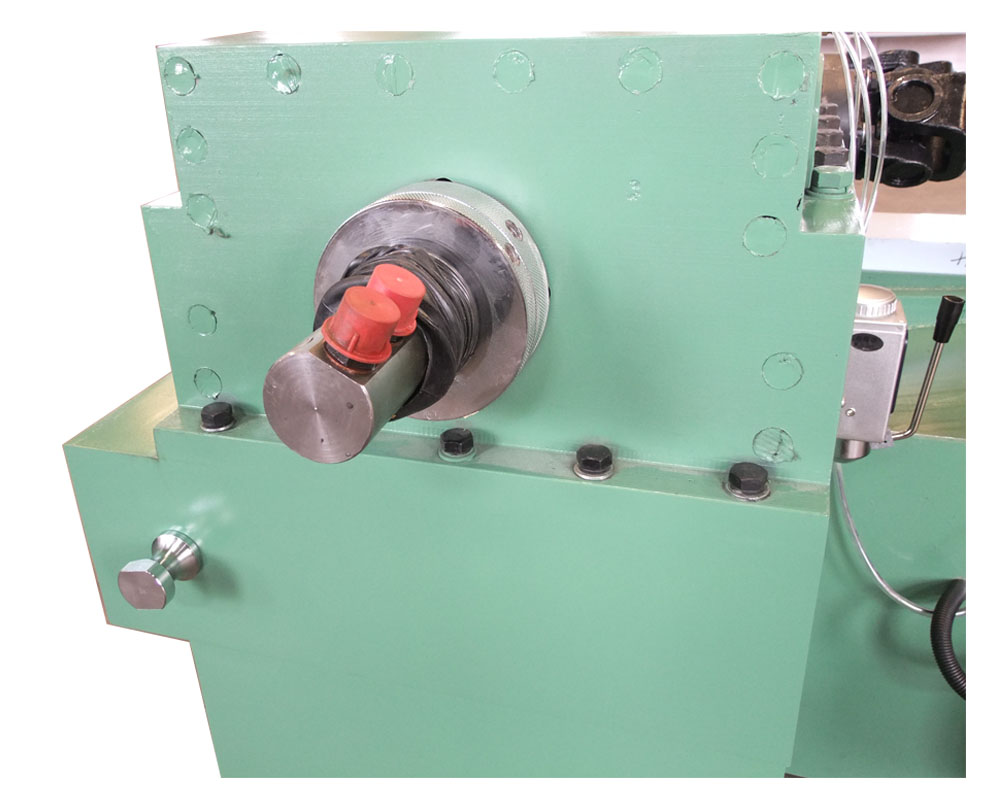

Z28-200 type thread rolling machine is mainly used for rolling all kinds of precision external thread and high strength standard parts, including ordinary thread, trapezoidal thread and modular thread.

Suitable for rolling materials: various carbon steels, alloy steels and non-ferrous metals with an elongation of more than 10% and a tensile strength of less than 100kgf/mm².

Z28-80 type thread rolling machine is well received by users because of its solid structure, excellent manufacture, convenient maintenance and reasonable price. This product can be processed radially and axially, and can be processed with corresponding thread rolling wheel. , special-shaped bolts, through-wires (strips).

Z28-40 type thread rolling machine is suitable for rolling forming of diameter ∮4-∮16mm straight line, spiral pattern and twill in cold state. It can process tight wire and wire (strip) by assembling spiral rolling wheel.

This machine is welded and formed by steel plate. It has reasonable structure, simple control and reliable quality. It is an ideal equipment for producing non-standard thread and standard parts (bolts).

|

Type |

Z28-200 |

||

|

Maximum rolling pressure |

200KN |

Spindle inclination |

±10° |

|

Radial rolling diameter |

∮64mm |

Spindle speed |

20.25.41.51.64(r/min) |

|

Maximum rolling pitch |

8mm |

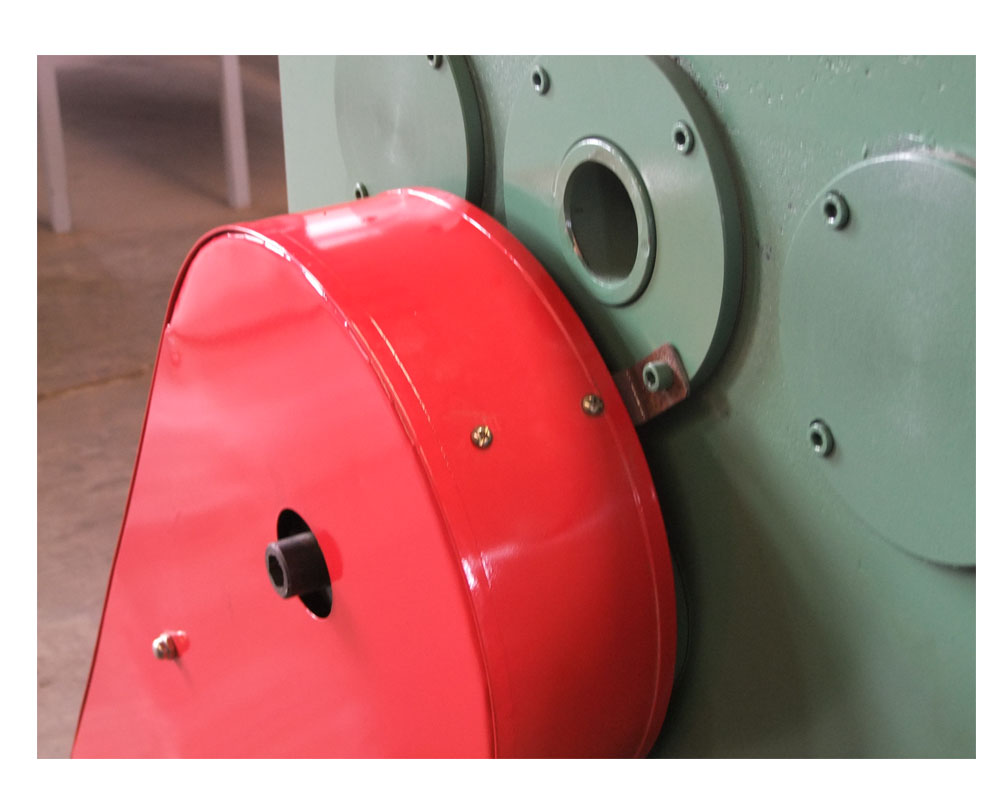

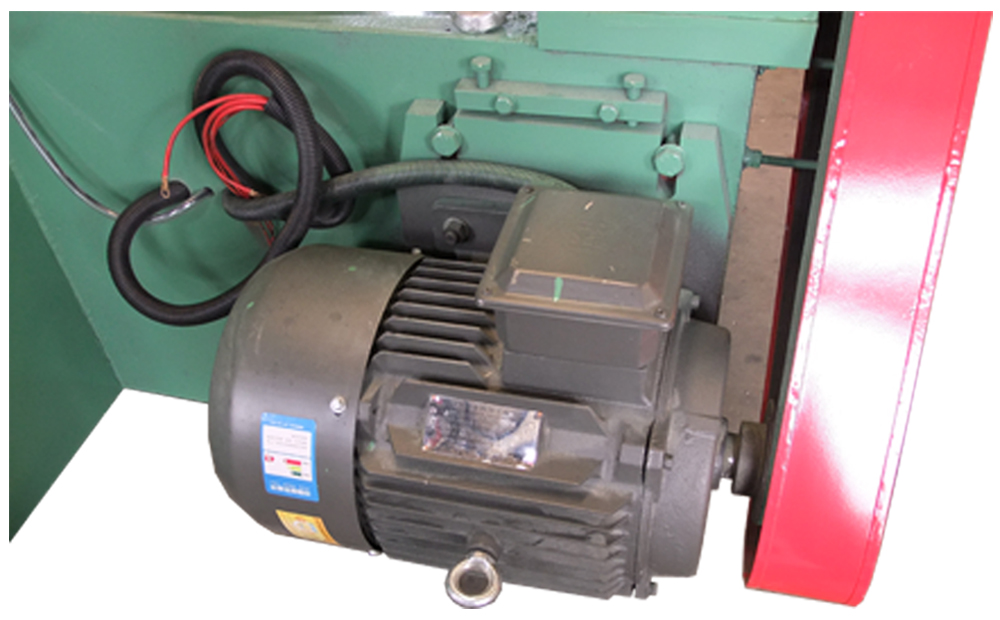

Rolling power |

11kw |

|

Rolling wheel maximum diameter |

∮220mm |

Hydraulic power |

5.5kw |

|

Rolling wheel aperture |

∮75mm |

Cooling power |

90w |

|

Rolling wheel maximum width |

150mm |

Total Weight |

3000kg |

|

Spindle center distance |

150-300mm |

Dimensions |

1790×1730×1430mm |

|

Type |

Z28-80 |

||

|

Maximum rolling pressure |

150KN |

Spindle speed |

36.47.60.78(r/min) |

|

Rolling material diameter |

Φ4-Φ48mm |

Active spindle feed rate |

5mm/s |

|

Rolling wheel outer diameter |

Φ120-Φ170mm |

Thread length |

Any (additional protection) |

|

Rolling wheel aperture |

Φ54mm |

Main power |

4kw |

|

Rolling wheel maximum width |

100 |

Hydraulic power |

2.2kw |

|

Spindle inclination |

±5° |

Total Weight |

1700kg |

|

Spindle center distance |

120-240mm |

Dimensions |

1480×1330×1440mm |

|

Type |

Z28-40 |

||

|

Maximum rolling pressure |

80KN |

Spindle speed |

36.47.60.78(r/min) |

|

Rolling material diameter |

4-36mm |

Spindle feed rate |

5mm/s |

|

Rolling wheel outer diameter |

Φ120-Φ170mm |

Hydraulic stroke |

0-20mm |

|

Rolling wheel aperture |

Φ54mm |

Main power |

4kw |

|

Rolling wheel maximum width |

100mm |

Hydraulic power |

2.2kw |

|

Spindle inclination |

±5° |

Total Weight |

800kg |

|

Spindle center distance |

80KN |

Dimensions |

1300×1250×1470mm |

© 2019 CHINA WAY. All Rights Reserved.Boron Machinery Manufacturing CO. LTD,Inc. All Rights Reserved. Sitemap. Sitemap.html