| Min. Order: | 1 Set/Sets |

|---|

Basic Info

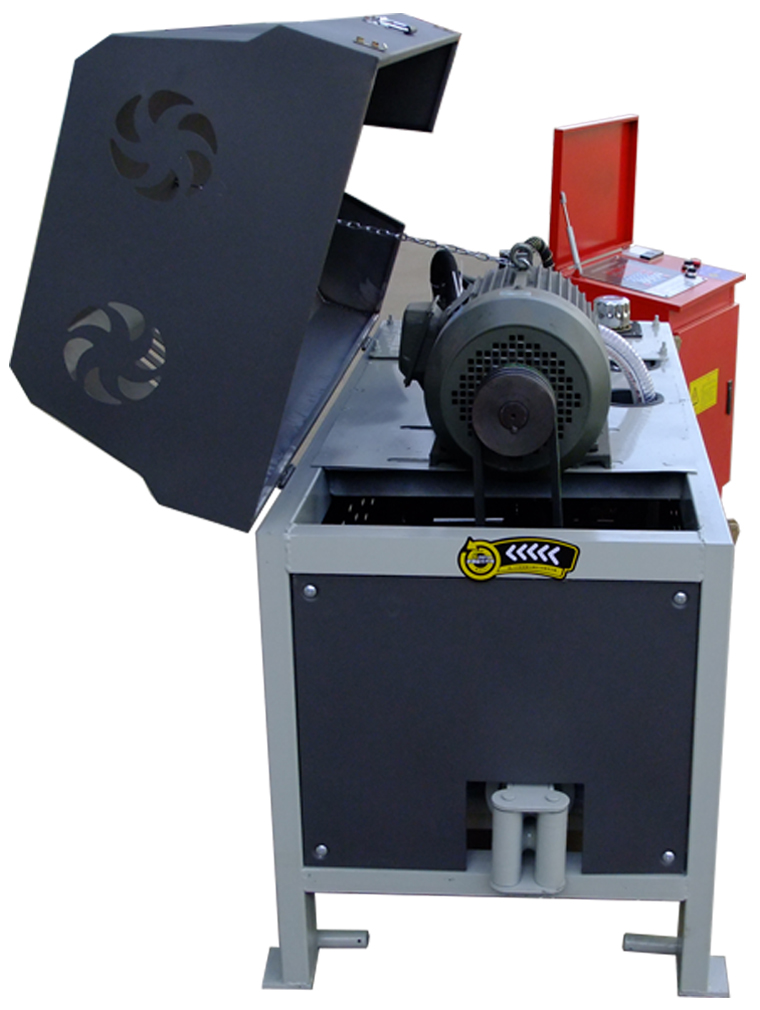

Model No.: YGT4-12

Applied material: Metal

Old and new: New

Whether CNC: Yes

place of origin: China

Certification: Iso, Iso 9001:2008

Core selling point: Long Service Life

warranty period: 1 Year

Out-of-warranty service: Video Technical Support, Online Support, Spare Parts

Applicable industry: Construction Works

Where to provide local services (in which countries are there overseas service outlets): None

Showroom location (in which countries are there sample rooms overseas): None

Mechanical test report: Provided

Video factory inspection: Provided

Marketing type: Ordinary Product

Core component warranty period: 1 Year

Suitable for: Other

Automation: Automatic

Total Weight: 700kg

Cut Length Error: ±5mm

Straightening Diameter Range: Φ4-Φ12mm

Straightening Speed: 50m/Min

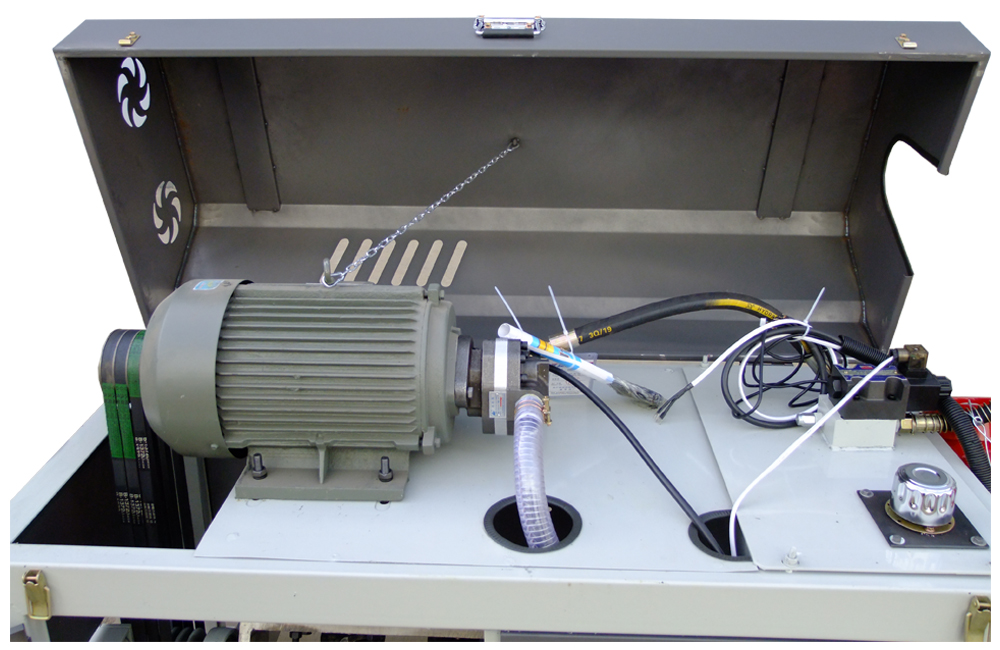

Traction Motor: 9kw

Cut Off The Motor: 4kw

Cut LengthCut Length: 30cm-9900cm

Dimensions: 2400×680×1300mm

Additional Info

Packaging: Wooden box

Productivity: 100 sets per month

Brand: Borong

Transportation: Ocean

Place of Origin: HeBei of China

Supply Ability: 100 sets per month

Port: Tianjin

Product Description

Equipment advantages:

1.It has the functions of automatic counting, preset cutting number, automatic stop after work completion, and steel guiding mechanism. Compared with other similar products of other manufacturers, the straightening frame adopts the hot rolling process, the appearance is beautiful, the rigidity is stronger, the straightening effect is good; the hydraulic system is simple and reliable, does not leak oil, does not block the valve.

2. Fast cutting efficiency: Due to the use of frequency conversion controller, the maximum cutting speed of this machine is 90 m / min, which is 2-3 times of the current similar equipment.

3.The accuracy of the fixed length: due to the use of CNC shear control, the dimensional accuracy is accurate, the cut length error is ≤ ± 1mm and the adjustment is simple.

4. High straightening accuracy: the straight line height of the straightened steel bar is ≤2mm/m, which is higher than the precision of the similar machine and equipped with high durability tungsten steel wear block.

5. Can be broken steel: the shortest controllable cutting length is only 0.3 meters, which is impossible for the same kind of machines.

6. Low failure rate: Due to the use of PLC and frequency conversion controller, the parts are processed finely and the quality control is strict, which can guarantee trouble-free operation for a long time.It can be disassembled, easy to handle and install, and equipped with numerical control device, which can be customized according to different requirements of customers.

7. Straightening speed is fast, no error is cut, no noise, no continuous cutting, adjustable straight Φ4-Φ12 disc round bar and Φ4-Φ10 grade stud bar, suitable for all kinds of construction sites and steel bar processing.

Product description

The fully automatic CNC hydraulic bar straightening cutting machine is a machine used for straightening and rebaring of steel bars on construction sites. It is suitable for straightening and cutting of ordinary disc snails on construction sites, steel processing shops, etc. Equipped with a computer numerical control panel, easy to operate and agree to get started. This shop has a variety of models, please contact customer service for details.

Precautions for use

1. The steel bar must be cut at the middle and lower part of the tool. If it is not necessary, the upper part of the tool should not be used to avoid excessive fatigue of the tail of the machine.

2. When the shape of the fixed blade is rectangular (84x70mm/90x74mm) and the steel bar of φ32mm/38mm or less is cut, the long edge is used as the cutting edge. When cutting steel bars of φ32mm/38mm or more, use the short side to make the cutting edge, and pay attention to check whether the blade is loose during use. After the blade edge is chipped, the tool should be changed or replaced with a new one in time to avoid the cutting resistance increasing after the blade is blunt and damage other parts. (The position where the fixed blade is cut below φ32mm/38 when the machine is shipped from the factory)

Maintenance and lubrication

1. Clean all parts of dust, debris and rust in time to prevent oil from rust.

2. Always check whether the oil level in the machine cavity is above the oil mark.

3. If the machine stops working for a long time, the motor needs to be removed.

4. After the first refueling, the new oil should be replaced after one month. After 6 months, the bearing should be added with calcium grease (butter).

Technical parameter

|

Straightening diameter range |

Φ4-Φ12mm |

|

Straightening speed |

50m/min |

|

Cut length error |

±5mm |

|

Traction motor |

9KW |

|

Cut off the motor |

4KW |

|

Cut length |

30cm-9900cm |

|

Total Weight |

700kg |

|

Dimensions |

2400×680×1300mm |

As a professional machinery manufacturer, we do have different kinds of construction machinery. Thread Rolling Machine For Sale, contact me if you need it. We will offer you a reasonable Roll Thread Machine Price and best Thread Rolling Services. Besides this Z28-80, we do have Z28-200 Type Thread Rolling Machine, they are both High Speed Thread Rolling Machine. Also we have Steel Straightening Machine, Rebar Bending Hoop Machine, Hydraulic Concrete Converying Transport Pump, and so on. The most important, it can be customized according to various needs.

© 2019 CHINA WAY. All Rights Reserved.Boron Machinery Manufacturing CO. LTD,Inc. All Rights Reserved. Sitemap. Sitemap.html