| Min. Order: | 1 Set/Sets |

|---|

Basic Info

Model No.: Multiple models

Certification: Iso 9001:2008

Application: Other

Condition: New

Control: Automatic

Power Source: Hydraulic

Layout: Other

Cut The Diameter Of The Steel Bar: Round Steel ¢ 4-¢12mm; Thread ¢ 4-¢10mm

Cut The Length Of The Bar: 0.15 M - 99 M

Speed Of Tapping: 31-45m / Min

Production Per Shift (8 Hours): ¢6 (3-4 Tons); ¢8 (4-6 Tons); ¢10 (8-10 Tons); ¢12 (10-12 Tons)

Enter Batch At The Same Time: Batch 1-20, Insert Batch: 1-10 Batch

Single Batch Cutoff Quantity: 1-9999

Power Supply: 380v / 50h Three-Phase Ac; 220v / 50h Three-Phase Ac

Motor: 7.5kw (Type 10)

CNC Box Power: ≤15w

Dimension: 130 Cm (Length) X 53 Cm (Width) X 80 Cm (Height)

Additional Info

Packaging: Wooden box

Productivity: 100 Sets per month

Brand: BoRong

Transportation: Ocean

Place of Origin: HeBei of China

Supply Ability: 100 sets per month

Port: Tianjin

Product Description

Product description

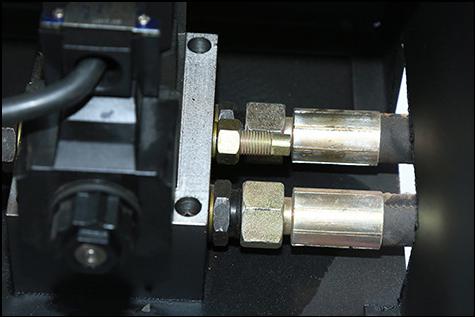

The fully automatic CNC hydraulic bar straightening machine is a machine used for straightening and rebaring of steel bars on construction sites. It is suitable for straightening and cutting of ordinary disc snails on construction sites, steel processing shops, etc. Equipped with a computer numerical control panel, easy to operate and agree to get started. This shop has a variety of models, please contact customer service for details.

Precautions for use

1. The steel bar must be cut at the middle and lower part of the tool. If it is not necessary, the upper part of the tool should not be used to avoid excessive fatigue of the tail of the machine.

2. When the shape of the fixed blade is rectangular (84x70mm/90x74mm) and the steel bar of φ32mm/38mm or less is cut, the long edge is used as the cutting edge. When cutting steel bars of φ32mm/38mm or more, use the short side to make the cutting edge, and pay attention to check whether the blade is loose during use. After the blade edge is chipped, the tool should be changed or replaced with a new one in time to avoid the cutting resistance increasing after the blade is blunt and damage other parts. (The position where the fixed blade is cut below φ32mm/38 when the machine is shipped from the factory)

Use of pedal clutch

1. After the steel bar to be cut is placed in the cutting position, the eccentric iron (octagonal iron) is attached to the steel bar with the appropriate edge, and the pedal can be cut off with the pedal pedal. The pedaling time must not exceed 2 seconds, otherwise the knife will be sent continuously.

2. If you want to cut continuously, you can control the M8 bolt on the fork and pull the brake pin out to cut it continuously.

3. This machine removes the inner pad of the tiger's mouth and replaces the special blade for the angled steel. The angled steel can be cut (the angled steel blade needs to be ordered)

4. When the pedal is in the clutch, the clutch should be put into position, and often the virtual step is not in place, which will cause premature clutch damage.

Maintenance and lubrication

1. Clean all parts of dust, debris and rust in time to prevent oil from rust.

2. Always check whether the oil level in the machine cavity is above the oil mark.

3. If the machine stops working for a long time, the motor needs to be removed.

4. After the first refueling, the new oil should be replaced after one month. After 6 months, the bearing should be added with calcium grease (butter).

As a professional machinery manufacturer, we do have different kinds of construction machinery. Thread Rolling Machine For Sale, contact me if you need it. We will offer you a reasonable Roll Thread Machine Price and best Thread Rolling Services. Besides this Z28-80, we do have Z28-200 Type Thread Rolling Machine, they are both High Speed Thread Rolling Machine. Also we have Steel Straightening Machine, Rebar Bending Hoop Machine, Hydraulic Concrete Converying Transport Pump, and so on. The most important, it can be customized according to various needs.

© 2019 CHINA WAY. All Rights Reserved.Boron Machinery Manufacturing CO. LTD,Inc. All Rights Reserved. Sitemap. Sitemap.html