| Unit Price: | USD 4500.0000 - 5000.0000 / Piece/Pieces |

|---|

Basic Info

Warranty Service: 1 Year

After-sales service: Online Technical Support

Engineering solution capability: Others

Application scenario: Other

design style: Modern

place of origin: China

Power: 1.5kw

Voltage: 220v/380v

Efficiency: 500 square meter/8h

Plastering Way: Vibration Plastering

Vibrator: 3 Vibrators

Plastering Height: ≤5m

Plaster Width/time: 80cm

Plastering Thickness: 5-30mm

Perpendicularity Degree: Max 2mm

Console Dimension: 2.6m*0.3m*0.23m

Additional Info

Packaging: Wood Case

Productivity: 100 sets per month

Brand: Borong

Transportation: Ocean

Place of Origin: HeBei of China

Supply Ability: 100set/week

Port: Qingdao,Tianjin

Product Description

Product description

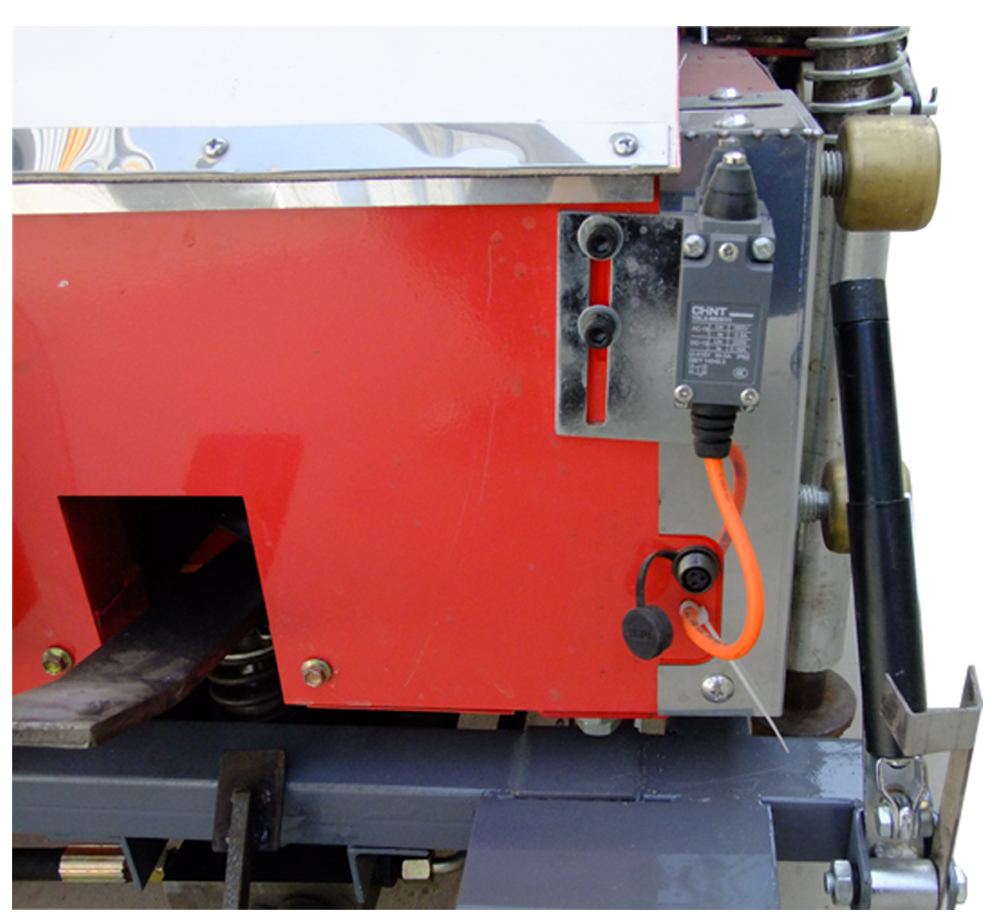

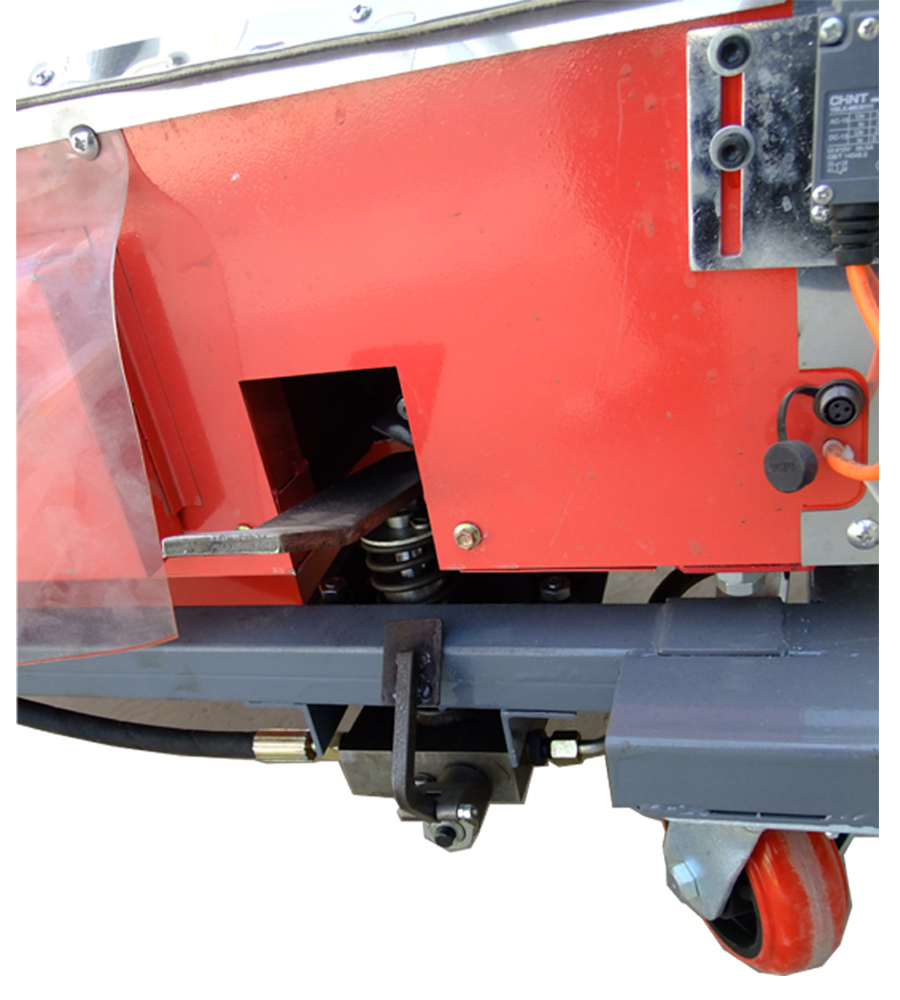

Our stucco wall machine can be completely wiped to the top without leaving a distance of one millimeter, and the yin and yang angles can be used in the proper position. At the same time, the positioning is fast, the positioning is very fast, and it can be flattened vertically in about 10 seconds. Combining the two departments and traditional management, the problem of slow laser positioning, difficult positioning and large error is solved. The use of a vibrator and the addition of a wiper solves the problem that the artificial applicator wall is prone to hollowing and cracking.

The machine has the advantages of simple operation, beautiful appearance, stable operation, sturdy and durable, convenient movement, rapid positioning and no need for disassembly, which greatly improves the material utilization rate and engineering progress.

Plastering machine plastering technology

(First) Plastering works:

In order to ensure the quality of the plastering project and avoid cracks, hollow drums, ash, etc., the following practices and measures are taken:

1. The mortar used in the plastering project should be stirred in strict accordance with the mix ratio.

2. The mix ratio and consistency of the plastering mortar should be used only after passing the inspection. Mortar mixed with cement or gypsum should be controlled to be used before initial setting.

3, in the construction in strict accordance with the normative standards to request and guide the construction: yin and yang angle to find the side, set the standard ribs, layering leveling, dressing, surface calendering.

4. Before the plastering, the brick wall must be watered and wetted in advance.

5. When admixture is used in the mortar, the amount of the admixture should be determined by experiment.

6, Plaster with lime paste, drenched with chunks of lime, must be sieved with a sieve with a pore diameter of not more than 3mm × 3mm, and stored in the sedimentation tank. Curing time: generally not less than 15 days at room temperature, not less than 30 days when used for covering. The lime paste must not contain uncooked granules and other impurities during use.

7. For indoor walls, cylinders and corners of the door, it is advisable to use 1:2.5 cement mortar as the corner guard. The height should not be less than 2m, and the width of each side is not less than 5cm.

8. The pre-embedded line pipe groove of the wall is first filled with 1:2 cement mortar and 3% expansion agent. The reserved hole on the wall is filled with C20砼 with 3% expansion agent. After the wire mesh is nailed, it is plastered. .

(Second) Plastering of the outer wall of the outer wall:

1. Grassroots cleaning:

Before the exterior wall is smeared with ash, the mortar, wood chips, loose crepe parts, etc. remaining on the surface of the base layer are cleaned and watered.

2. The outer wall reserved hole is filled:

(1) Firstly, the residual mortar, loose lumps, stones, etc. in the reserved hole are chiseled off, and the outer sides are chiseled into the outer eight bell mouths, and washed with water.

(2) Apply a cement slurry with a water-cement ratio of 0.4 to 0.5 in the vicinity of the wall of the cave.

(3) The two side molds fill the dry hard enthalpy of the proper amount of expansion agent and water repellent.

3. The external wall screw hole is filled:

(1) Both sides of the screw hole are chiseled into an outer bell mouth, and the sleeve inside is cut off.

(2) Fill the holes with a 1:2 dry hard cement mortar with an appropriate amount of expansion agent and water repellent plug.

(3) The round steel (outer water sealing tape) of the corresponding diameter is clamped into the PVC casing at both ends by about 5 cm.

(4) Seal the PVC casing shearing surface with waterproof material, and then fill the bell mouth with cement mortar (with appropriate amount of expansion agent and waterproof agent).

4. According to the design requirements, the 10×10 chute should be cut at the junction between the shear wall and the masonry, and the next step can be carried out after filling with the waterproof grease.

Tech Parameter

|

Efficiency |

500 square meter/8h |

|

Power |

1.5kw |

|

Voltage |

220v/380v |

|

Plastering way |

Vibration plastering |

|

Vibrator |

3 vibrators |

|

Plastering height |

≤5m |

|

Plaster width/time |

80cm |

|

Plastering thickness |

5-30mm |

|

Perpendicularity degree |

Max 2mm |

|

Level degree |

Max 2mm |

|

Moves |

Automatic Walking |

|

Lifting speed |

3.6 m/30s |

|

Host Dimension |

1.05m*0.8m*0.8m |

|

Console Dimension |

2.6m*0.3m*0.23m |

|

Total Dimension |

0.9 cubic mete |

As a professional machinery manufacturer, we do have different kinds of construction machinery. Thread Rolling Machine For Sale, contact me if you need it. We will offer you a reasonable Roll Thread Machine Price and best Thread Rolling Services. Besides this Z28-80, we do have Z28-200 Type Thread Rolling Machine, they are both High Speed Thread Rolling Machine. Also we have Steel Straightening Machine, Rebar Bending Hoop Machine, Hydraulic Concrete Converying Transport Pump, and so on. The most important, it can be customized according to various needs.

© 2019 CHINA WAY. All Rights Reserved.Boron Machinery Manufacturing CO. LTD,Inc. All Rights Reserved. Sitemap. Sitemap.html